UPLOAD FILES

Suitable file types: Illustrator (.ai) & AUTOCAD (.dxf)

The basis is that the file should consist of lines (vectors) and not of pixels (such as an image). In some cases it is relatively easy to convert a (high resolution) image to a line drawing, for more information you can contact us.

Are you unable to realize a digital drawing yourself? Do you need help in developing your design? We offer help and advice to make a design producible for both a single and a series of products. Also check design and advice.

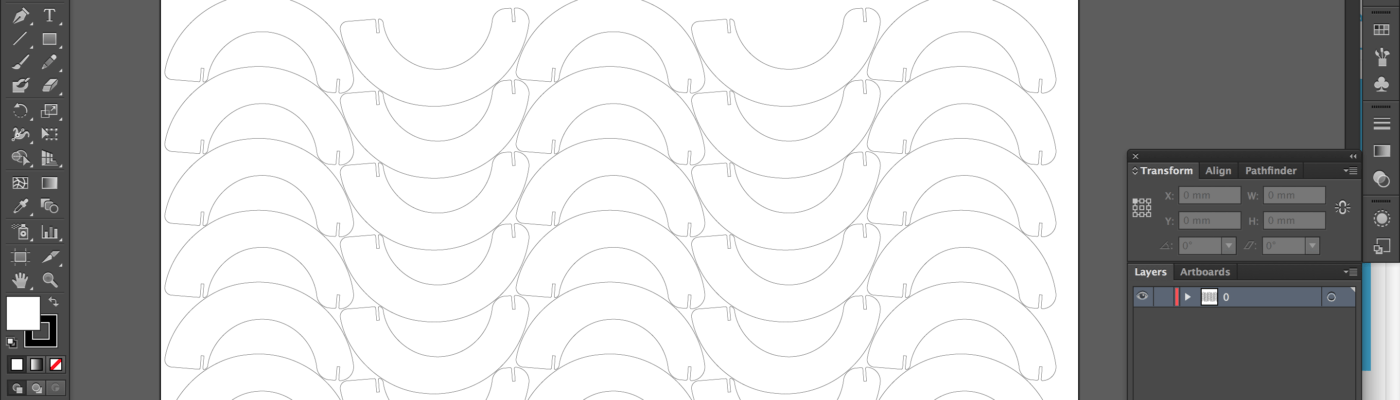

cut drawing templates

To avoid mistakes, we ask you to use our cut drawing templates for a cutting request. These can be downloaded below. The materials that we stock in stock have different sizes. Therefore use the template that has the format of the material. Do you want to use multiple plates of the same material? Then make multiple drawings.

1000 X 600 MM

– 1 mm birch plywood

– 2 mm birch plywood

– 0,5 mm Polypropylene

– 0,8 mm Polypropylene

– 3 mm Acrylate glossy color

– 3 mm Acrylate gold/silver

– 4 mm Acrylate transparent

– 5 mm Acrylate transparent

– 6 mm Acrylate transparent

– 1 mm grey cardboard

– 2 mm grey cardboard

– 3 mm grey cardboard

– 1 mm brown cardboard (kraft)

– 1 mm White/black cardboard

– 2 mm White/black cardboard

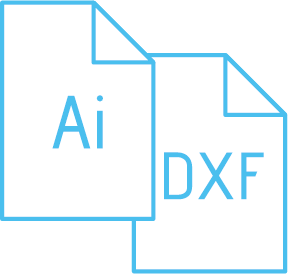

design guidelines

| Max. size of drawing: | Depends on material(thickness) |

|---|---|

| Margin: | Allow a margin of 5 mm from the sides without cutting or engraving lines. |

| Scale: | Draw scale 1:1, using millimeters as unit |

| File format: | .DXF (Autocad-file, fromIllustrator: ‘Export’ to . dxf) |

| Lay out: | ‘Basic’ drawings: remove all objects except cut and engraving lines (so no measurement lines, centre lines, etc.) |

| Stroke: use thin lines (0.2mm or hairline) | |

| Ungroup all objects, and make sure that all your lines are joined together into one path. (Illustrator: commando ‘Join’) |

|

| Remove all infill’s (fills, hatches, etc.) | |

| Remove objects in invisible or frozen layers | |

| Remove all clipping masks | |

| Be careful: every line will be cut! If you have multiple lines on top of each other they will all be cut. | |

| Text: | Create outlines of texts. (Illustrator: command ‘Create Outlines’, CAD programs: command ‘Explode’) |

| Nest: | Putting all parts from the same material together on one sheet in the most materially efficient way to go. |

| Width: | A cutting line is about 0.15/0.2mm thick, depending on the material and the material thickness |

| Engraving: | Do you want to have something vector or raster engraved? Click here for more information and check below for our guidelines. |

Guidelines for laser engraving

Do you want to cut as well as engrave? Put the cutting paths in one layer and the engraving paths in another, and colour the paths as below:

| Layer name | Line colour |

|---|---|

| cut | blue (RGB 0,0,255) |

| vector engrave | red (RGB 255,0,0) |

| raster engrave | green (RGB 0,255,0) |

DESIGN & ADVICE

Digital drawing and modelling

CRE8 gladly supports you in the process from idea till design. We like to think along with you during your project, making the digital drawing and fabricating your design with our 3laser cutter. Laser cutting requires a so called vector-file, drawn in programs like AutoCAD, Illustrator and Inkscape. Besides drawing our scanners are able to scan drawings and turn them into digital representations. Thus, in short, even a simple sketch, photo or model can be transformed in a digital file our printers can work with.

CONTACT USProduct development

Thanks to years of working in product development and product marketing we have gained a lot of knowledge and experience of the design profession. This has allowed us to develop an overview of different kinds of market segments, enabling us to effectively think along with you when it comes to your own designs. We can use this knowledge to develop cost efficient ideas and/or 2D/3D designs into concrete products to be created as a one-off, or as a full product run. During the design process our facilities enable us to test the design at all stages, from creating preliminary models to final prototypes, allowing you to adjust the design along the way and have it manufactured according to your needs.

CONTACT USOne stop innovation shop

Is your company considering to innovate by launching a new product? Do you have an idea already, but no idea how to realize it? We like to help you out in developing and optimizing a market strategy, mapping the real needs of your customers and capturing this a program of requirements.

CONTACT US