LASER ENGRAVING

Our laser cutters are not only capable of cutting through materials, we can also make engravings on them. Materials that are suitable for laser engraving are wood, plastic, cardboard, textiles (such as leather), rubber and even metals and even stone! In addition, our rotation module also offers the possibility to engrave round objects. Large and small objects, single items or entire series productions, CRE8 is also the right place for you to engrave!

WOULD YOU LIKE TO:

MAKE AN ENGRAVING ON A PRODUCT OR MATERIAL (THAT YOU SUPPLY)?

WOULD YOU LIKE TO:

MAKE A ENGRAVING ON A PRODUCT OF CRE8?

WOULD YOU LIKE TO:

APPLY AN ENGRAVING ON A MATERIAL OF CRE8?

Then follow the laser cutting procedure. The engraving file must contain a frame to cut out (or the entire plate must be used). Therefore, take a good look how the file must be supplied. If you have any questions, you can of course always call or email us.

MATERIALS (SUITABLE FOR ENGRAVING)

CRE8 can handle objects with a maximum size of 160 x 100 x 40 cm. In addition, the engraving can have a maximum size of 140 x 100 cm. If you want to have an engraving applied to the top of an object, then that object may have a maximum height of 40 cm.

WOOD ENGRAVING

Engraving wood is very well possible, both texts and patterns as well as images. Because wood can discolour in all kinds of shades, beautiful contrast-rich images can be created. When engraving, the wooden surface is burned, so that it becomes darker in color. The slower and more powerful the engraving is performed, the darker (and deeper) the result. One type of wood colors darker than the other, and one is softer than the other, allowing deeper engravings to be created.

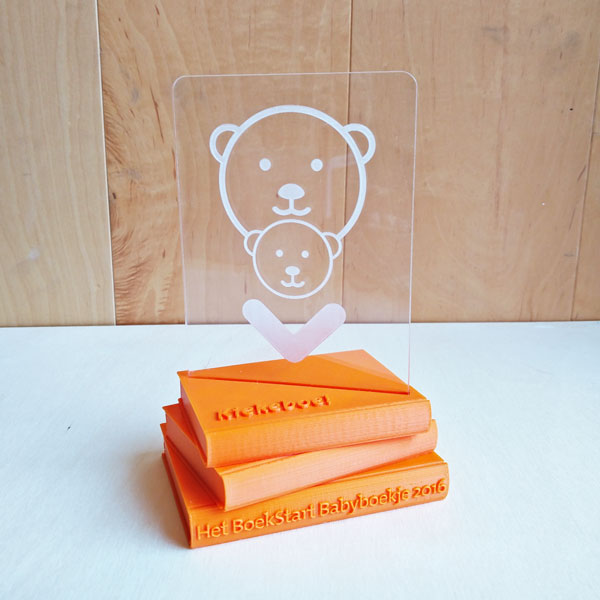

PLASTIC ENGRAVING

Of the plastics that we have in stock as standard, acrylic gives great engraving results for texts and patterns and, to a lesser extent, for images. A nice contrast with the rest of the material can be achieved, but more difficult to achieve multiple shades (white). The PP and PS plates cannot be engraved properly, because the contrast is minimal.

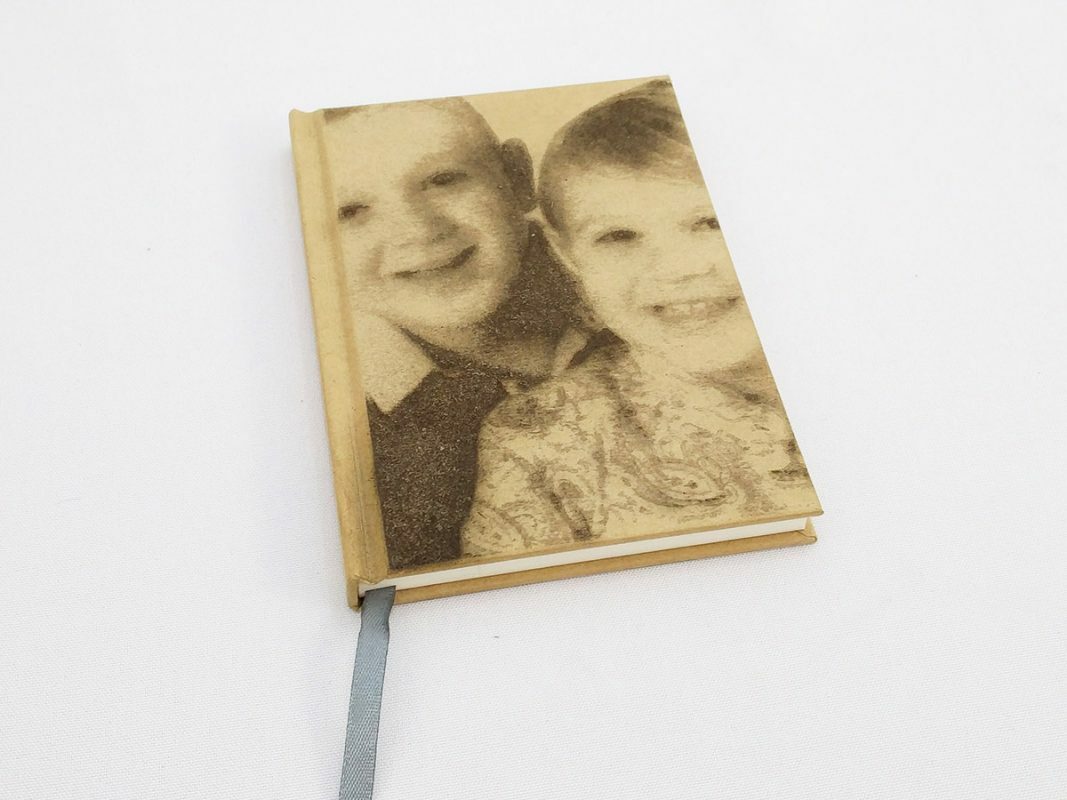

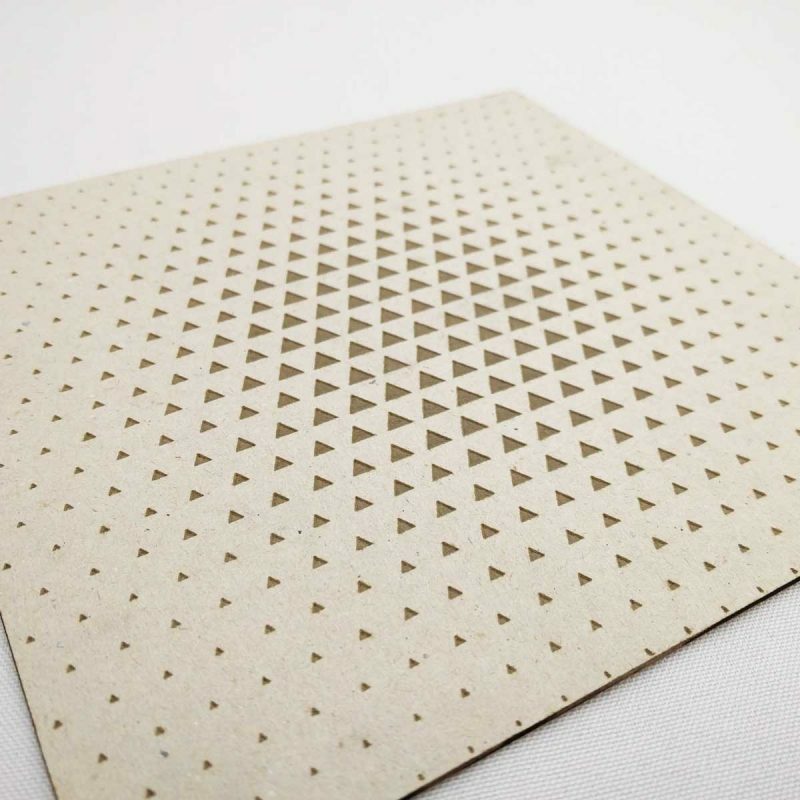

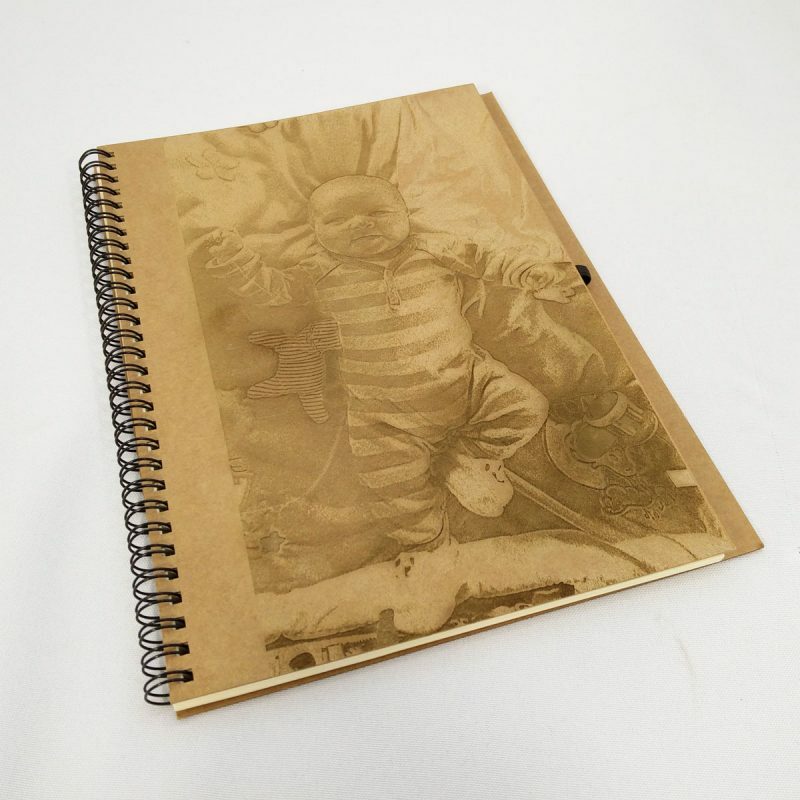

CARDBOARD ENGRAVING

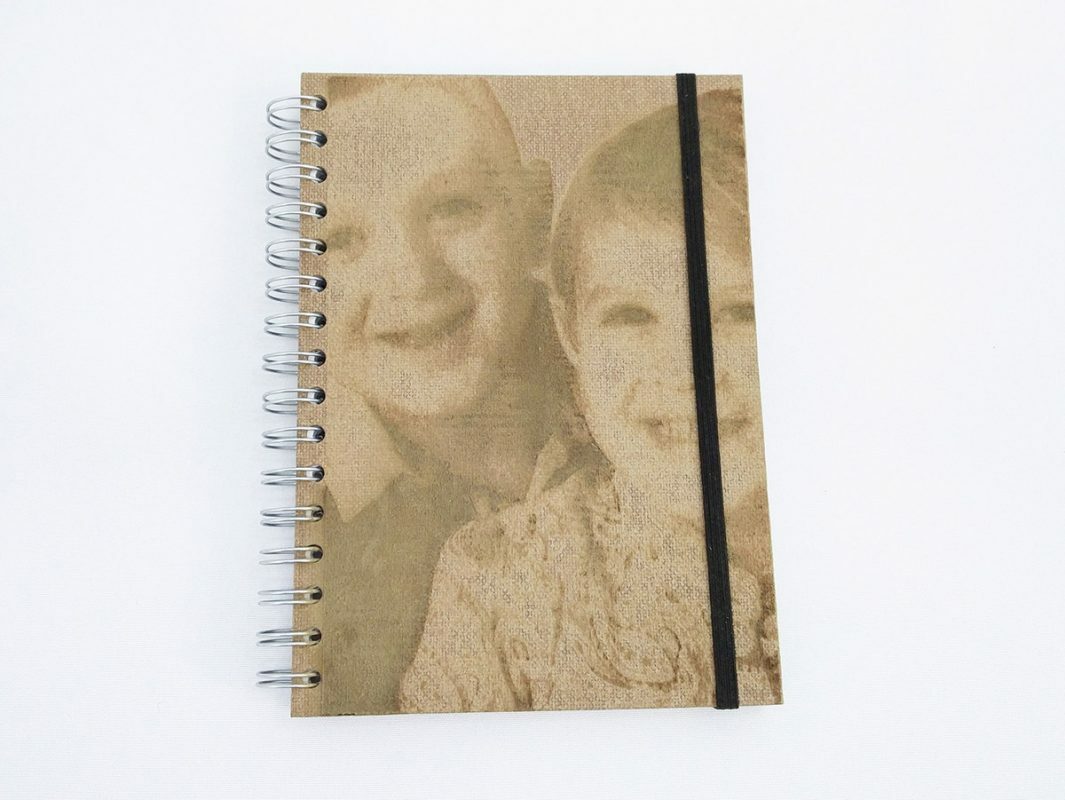

Solid cardboard is a good option for engraving, both texts and patterns as well as images. For example, for engraving the cover of a notebook or dummy. Conversely, Brown kraft cardboard , which CRE8 has in stock in stock, cannot be engraved properly. That is why it is always wise to have us first do a test in the desired cardboard. Corrugated cardboard cannot be engraved.

LEATHER / TEXTILE ENGRAVING

In theory you could argue that natural materials such as leather, cotton and linen produce good engraving results, because they burn and thus discolor dark. Synthetic fabrics tend to melt and the molten and solidified surface generally provides too little contrast to the rest of the fabric. But here too it is always the case that we first have to do a test of how things turn out.

metal engraving

Unlike cutting, CRE8 can engrave metals. We achieve excellent results when engraving raw steel, stainless steel, brass, aluminum, titanium, tin, copper and nickel. First we apply a special coating to the metal, which is then burned into the material by the laser beam. The result is a permanent, black-colored marking on the material. For a good result, the surface must not be treated with glossy paint or other coating.

WHAT IS POSSIBLE WITH ENGRAVING?

With an engraving, the material is engraved line by line. The line spacing is less than a tenth of a millimeter so that high resolution shapes and detailed illustrations can be made. This operation is relatively time-consuming, which means that production time and therefore costs can increase quickly with larger surfaces. Considerable time can be saved by elongating objects horizontally instead of vertically. Although flat engraving depth can be made, the technique is usually not economical to make deep cavities.

Texts and patterns

To engrave texts, the text in the digital drawing must be converted to ‘outlines’ (Illustrator: command “Create Outlines”, CAD programs: command “Explode”).

Images

We can also directly engrave images (consisting of pixels) on different surfaces. The nuances and contrasts within images are best visible on materials such as wood and cardboard and to a lesser extent on plexiglass. And with that also on products made from these materials such as notebooks, diaries, wine boxes, cutting boards and furniture. We can handle objects up to a height of approximately 40 cm! The image must, however, be converted to a bitmap. We can also do this for you.

Multiple shades possible with laser engraving

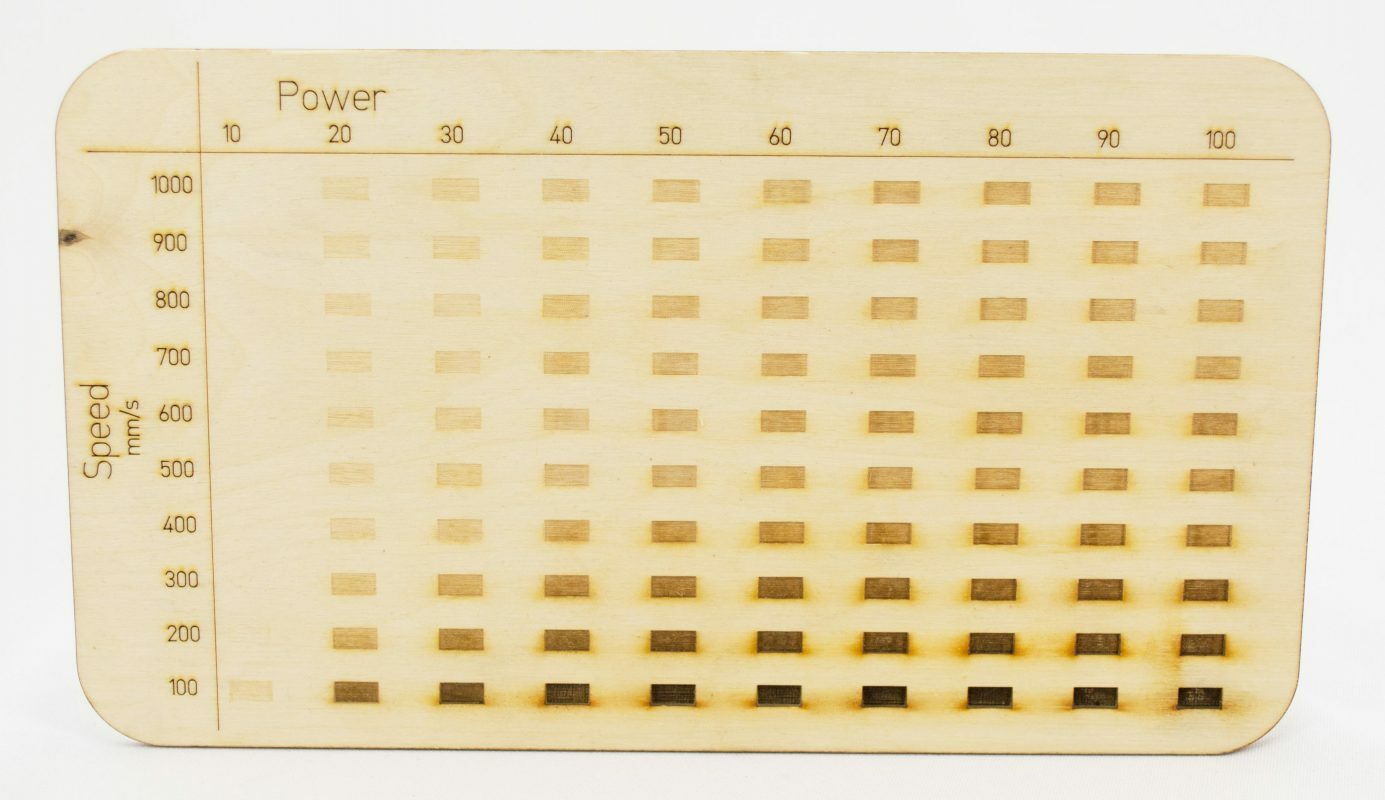

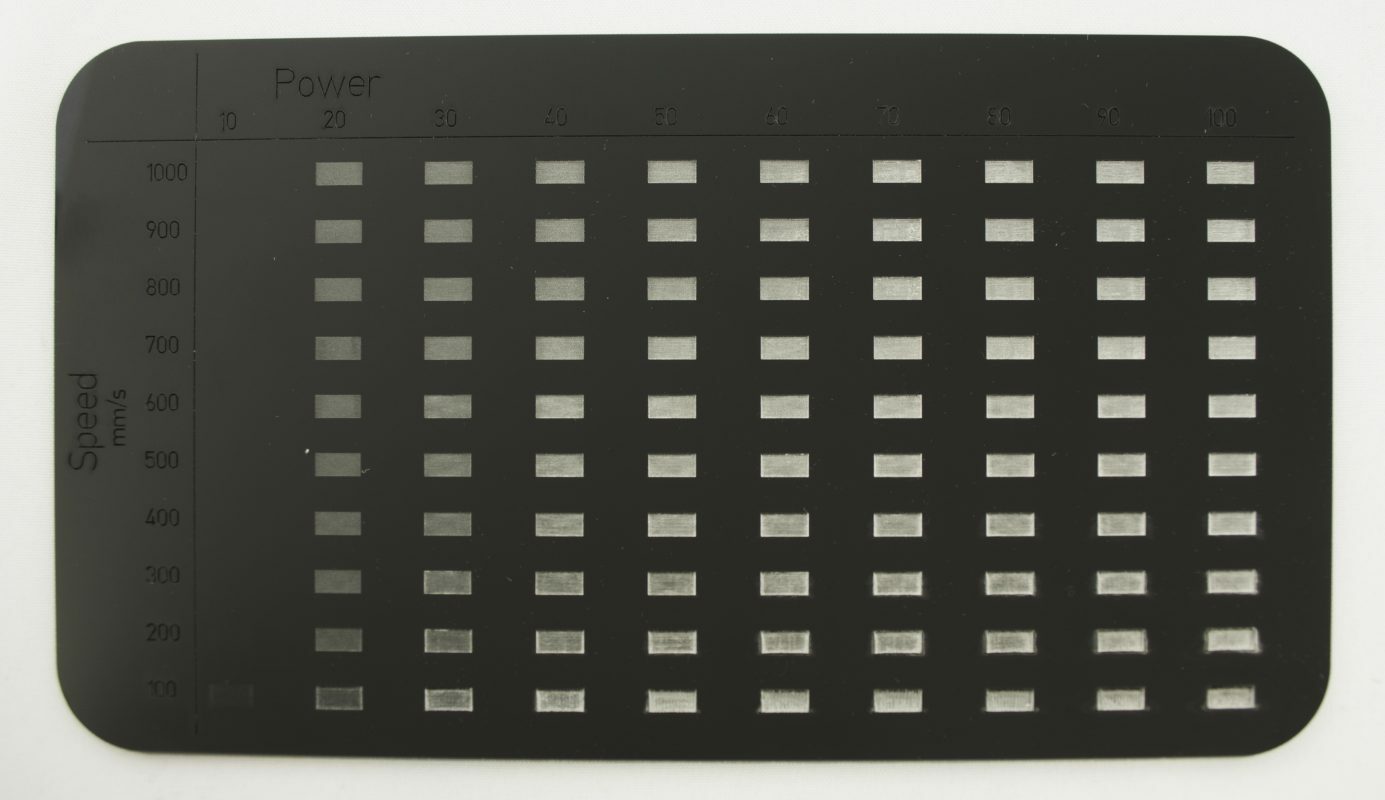

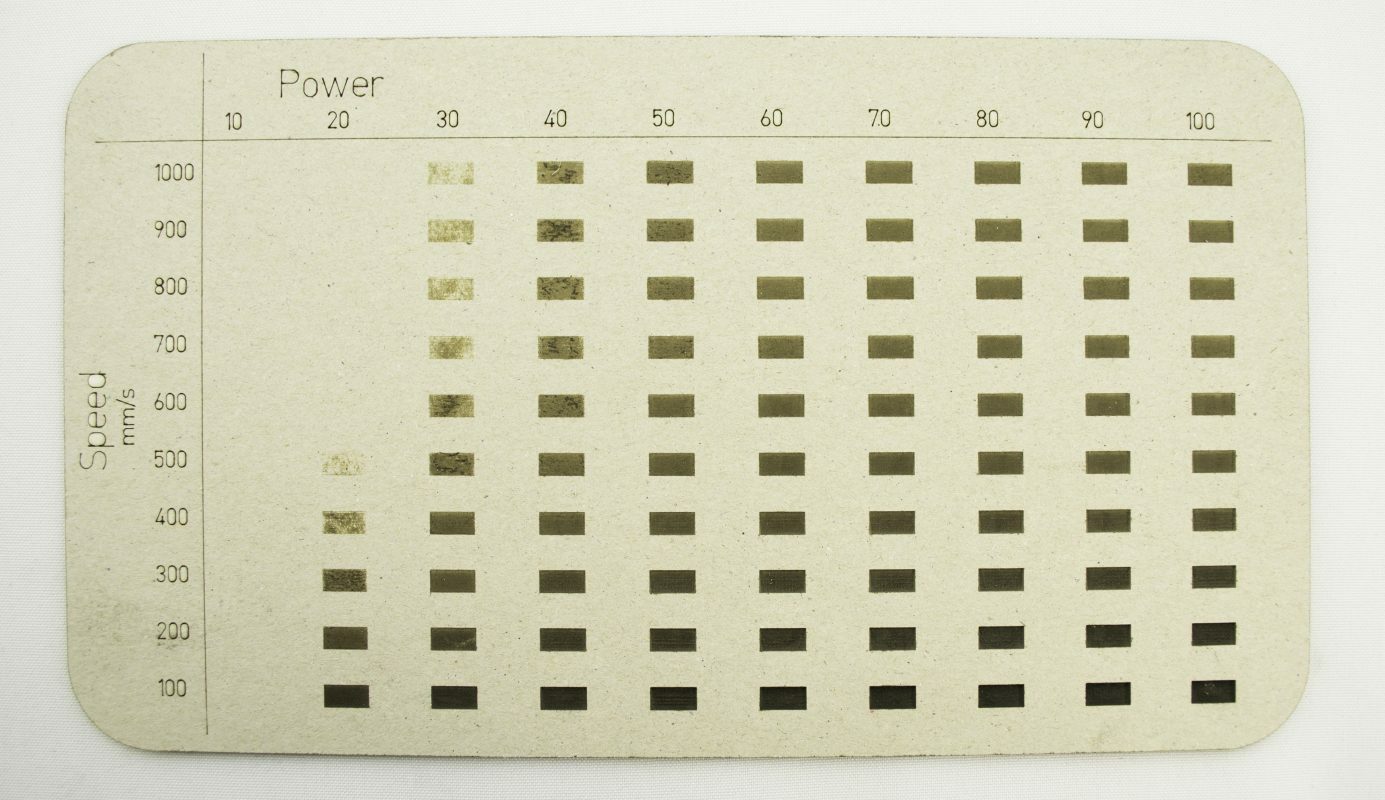

Color differences can be created by varying the speed and power of the laser. This offers a range of shades with which graphic expressions can be engraved with high accuracy and with a high contrast. Below you can see the test results of 3 materials for varying the speed and power of the laser beam. Engraving with a lot of power and low speed creates a darker (wood / cardboard) and deeper engraving. Visible as well is the limited variation in shades of acrylate.

| Plywood | Acrylate | Cardboard |

|---|---|---|

| Plywood colors in all kinds of brown tones | Acrylic is matted in various shades of white | Cardboard colors in all kinds of brown tones |

Engraving instead of milling

By engraving slowly and with high power we can realize deep engravings in different materials. Where milling has limitations in its freedom of form, every slot or hollow can be realized with high accuracy by means of laser engraving. Consider, for example, creating stamps with fine texts and / or images.