SCALE MODELS

CRE8 often works for architects for laser cutting materials for a model. In addition, more and more architects are discovering the possibilities of 3D printing fo creating an architectural scale model, from bridges to entire office buildings.

Laser cutting of model material

- CRE8 has a wide range of materials, standard in stock. You can also provide material yourself if desired.

- Not only are our laser cutters capable of cutting through materials, but also for applying engravings, for example to display façade panels and frames on the model.

- Delivery within 24 hours is possible

- With a maximum size of 160 x 100 cm we can also laser cut parts on a larger scale

- Given our background as graphic and industrial designers, we are happy to think along with you on design and technical issues.

- At CRE8 we train young people to become digital artisans through a work-learning trajectory. Not only do they learn to use 2D and 3D software, to operate the machines, but also to assemble the cutting into a product. They can therefore be of good service to you when building models, in the form of a (short) internship.

If you would like more information about the possibilities, please mail us.

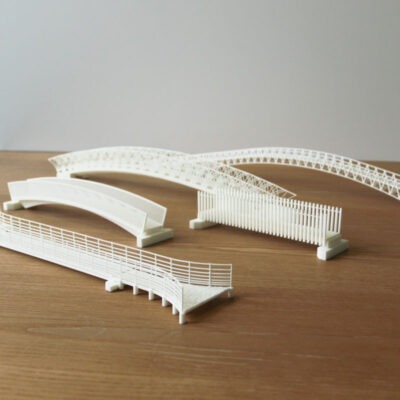

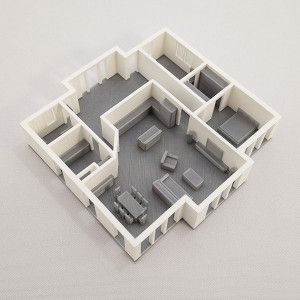

3D printing of a complete model

- CRE8 offers various 3D printing techniques which we can deploy depending on the form and application

- Depending on the size and printing technique, delivery from 1 day to 1 week is possible

- With a maximum size of 65 cm we can print your model 3D to a reasonable scale

- 3D printing requires a digital 3D model that is ‘watertight’, in other words, it must describe a solid form. The disadvantage of programs such as SketchUp is that it works with surfaces instead of solids. As these surfaces are not always aligned perfectly it won’t create a solid what is needed for printing. We can, however, remodel the object fairly quickly on the basis of such a model so that it can be printed.

For more information about the possibilities, mail us.

A combination of both production methods is of course also possible to create a beautiful model. For example we can cut and engrave the base plate, floors and straight facades. Shapes that are more difficult to describe by flat material, on the other hand, we could 3D print.