LASERCUTTING & -ENGRAVING

What is all possible with a laser cutter?

CRE8 has 3 laser cutters at its disposal with a maximum work area of 160 x 100 cm. Our laser cutters cut through materials like wood, plastic, cardboard and textile, but not metals. Furthermore they enable us to apply line (vector) and surface (raster) engravings to a variety of materials, even metals! Our rotation-module offers the opportunity to engrave on round objects.

Laser cutting is a technique that enables us to cut shapes in sheets of wood, cardboard, paper, plastic, leather and textile, by means of a laser beam. The highly concentrated laser beam cuts perpendicular through all kinds of sheet material, in any kind of shape and with a high precision. Based on a digital drawing, created in a program like Illustrator, we are able to realise your design in 1-3 work days. Send us your drawing(s) and you’ll receive a very competitive estimate within 24 hours.

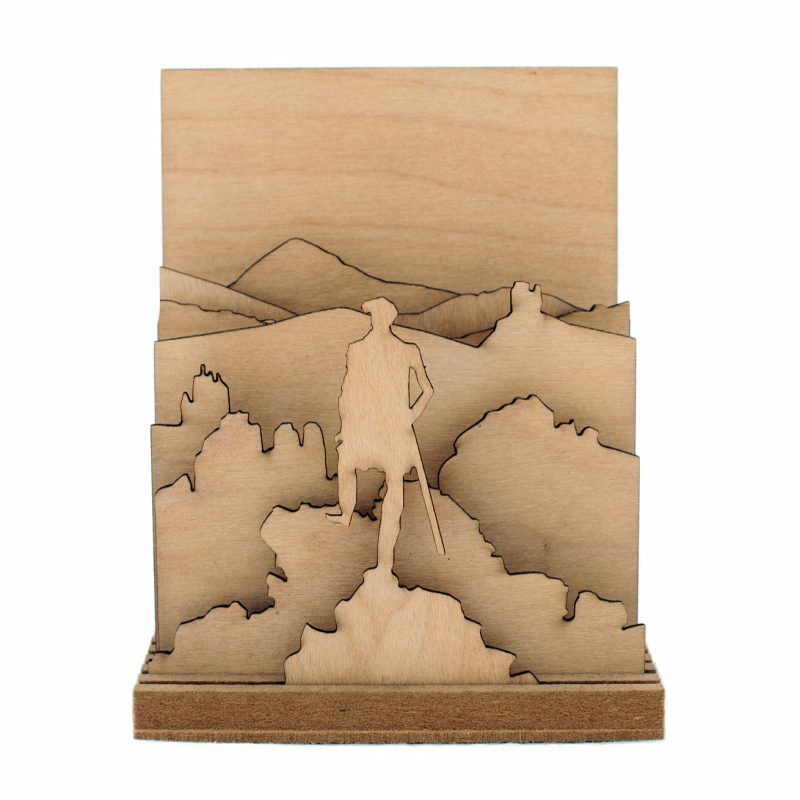

LASER CUTTING WOOD

| Available types: | Birch plywood in 1, 2, 3, 4 and 6 mm |

|---|---|

| Poplar plywood in 4, 6 and 9 mm | |

| Considerations: | Poplar plywood is about 40% cheaper and about 20% cheaper to cut than birch. Though poplar is softer and less stiff than birch, so choice depends on application. |

| The laser cutter creates a cutting line in wood by burning away the material, resulting in a brown coloured side of the material. | |

| The thickness of plywood can vary about 0.2 mm relative to the nominal thickness. Thus the thickness of a sheet of 3 mm could be between 2.8 and 3.2 mm in reality. Keep this in mind when designing fits. | |

| On the back side (and to a limited extent on the front side) the material could discolour around the cutting edge by means of the kickback of the laser. This discolouration can be just sanded away or we could add protection foil to avoid this. If you would like this please mention it in your application and we wil include this in the estimate. |

More info

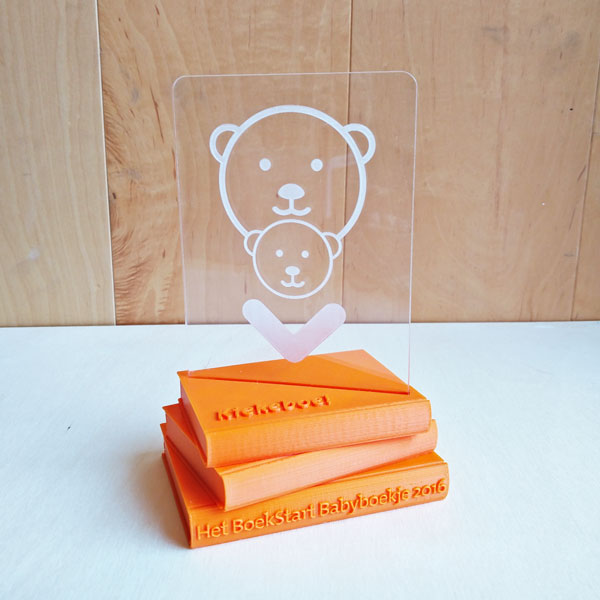

Laser cutting plastic

Acrylate is very well suited for displays or consumer products like jewelry and lighting. Acrylate or perspex or plexiglas is sensitive to scratches, that’s why in general we leave the protection foil on the sheet before and after cutting. The material is relatively brittle and so thin and oblong parts could break easily. The differences in thickness between or within the sheets are small.

| Available types: | Transparent and white PP (Polypropylene) foil in 0.5 and 0.8 mm |

|---|---|

| Matt white PS (Polystyrene) foil in 1 and 2 mm | |

| Transparent acrylate (perspex) in 2, 3, 4 and 6 mm | |

| Opal acrylate (perspex) in 2 and 3 mm | |

| Black, white and colored acrylate (perspex) in 3 mm | |

| Considerations: | The PP foils suit very well for making stencils. Furthermore they are applicable for making packaging and wrappers and folders, by cutting the material halfaway a film hinge can be created. |

| The laser cutter creates a cutting line in plastics by melting away the material and will not discolour the sides. Cutting the PP foil could result in accumulation of material along the edges. | |

| We have many colours of acrylate sheets standard in stock, other colours we could order for you of course. |

More info

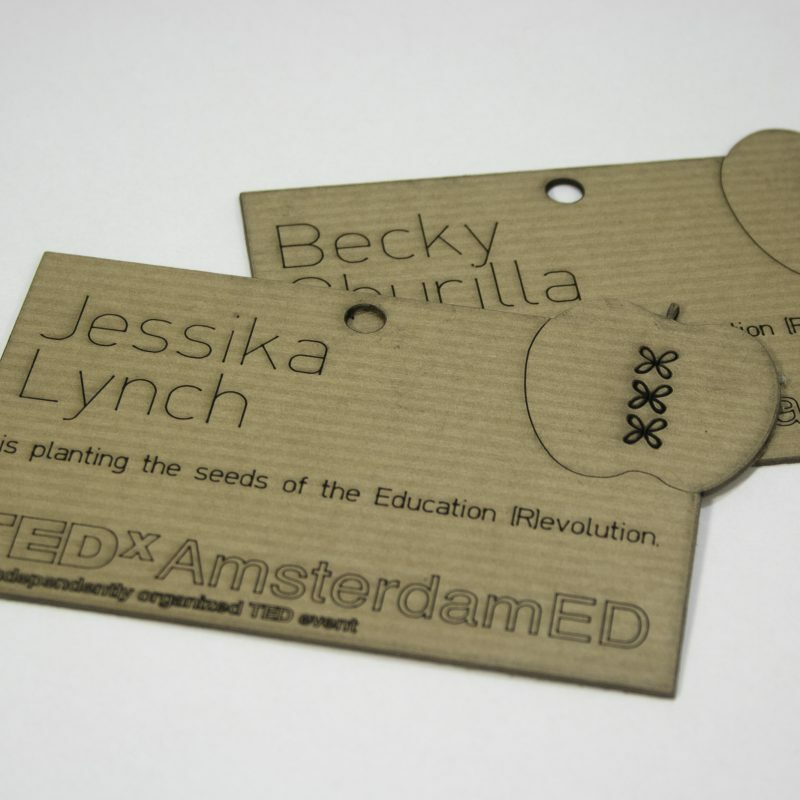

LASER CUTTING CARDBOARD/PAPER

Laser cutting of cardboard is a fine option for example for model building, displays and packaging. Creating a film hinge, by cutting the material halfaway (like PP foil) is not possible though, the material rips after a few bendings.

| Available types: | Grey cardboard in 1, 2 and 3 mm |

|---|---|

| Brown (craft) cardboard in 1 mm | |

| Black and white cardboard in 1 and 2 mm | |

| Brown corrugated cardboard in 1,5 and 2,5 mm | |

| Considerations: | The laser cutter creates a cutting line in cardboard and paper by burning away the material resulting in a brown/black coloured side. This gives off, but could be wiped away with a cloth. |

Meer info

LASER CUTTING TEXTILE

We can cut any fabric, if it’s synthetic or natural, no problem! Only thick pieces of leather could be difficult to cut or result in ugly cutting edge, since too much material needs to be burned away.

| Available types: | CRE8 doesn’t keep fabrics in stock. |

|---|---|

| Considerations: | The laser cutter creates a cutting line in the natural fabrics like cotton and leather by burning away material resulting in a brown/black side. This could give off, but can be wiped away with a cloth. With synthetic materials the material will melt away resulting in a non discoloured side. |

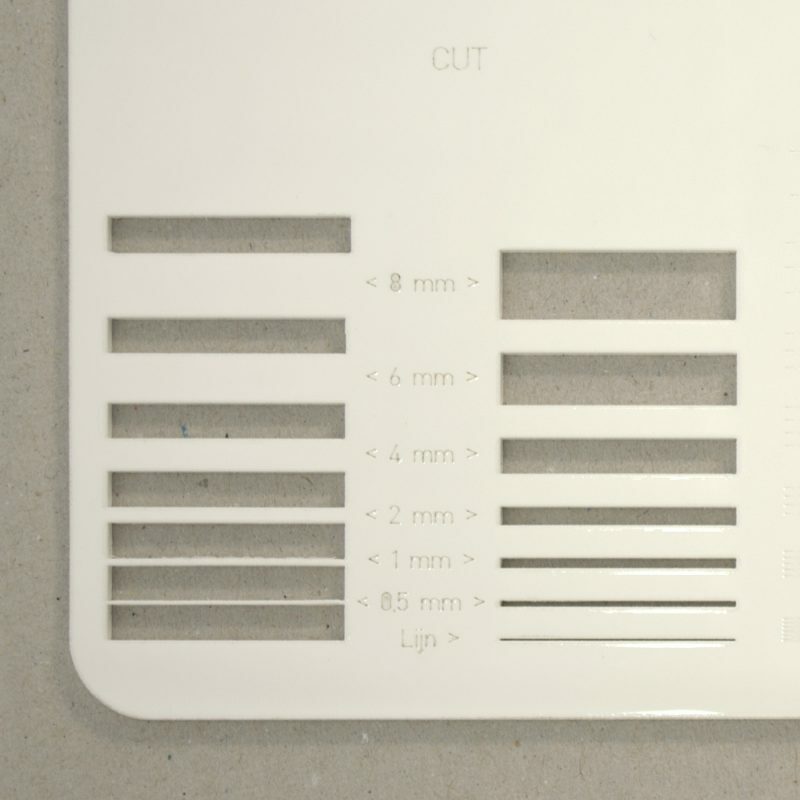

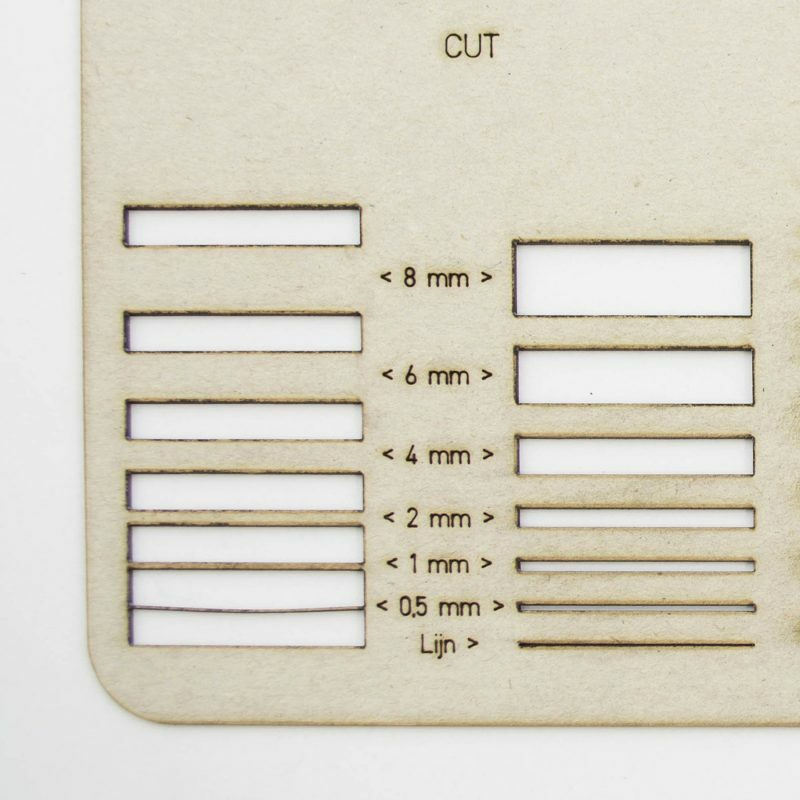

Vector engraving is a method of marking or scoring a material surface. Like the laser cutting process the laser beam will follow the path of vector strokes without cutting all the way through. The depth is usually not more than a few tenths of a millimeter, but this can vary. The width of the stroke is approx. 0.2mm.

| Wood | Black line with a good contrast | Leather | Black line with a good contrast |

|---|---|---|---|

| Acrylic | Colorless line, a bit matt with very little contrast. Best visibility in black or a dark colour | Metal | Black line with a good contrast |

| Cardboard | Black line with a good contrast |

Costs: Low

Guidelines laser engraving

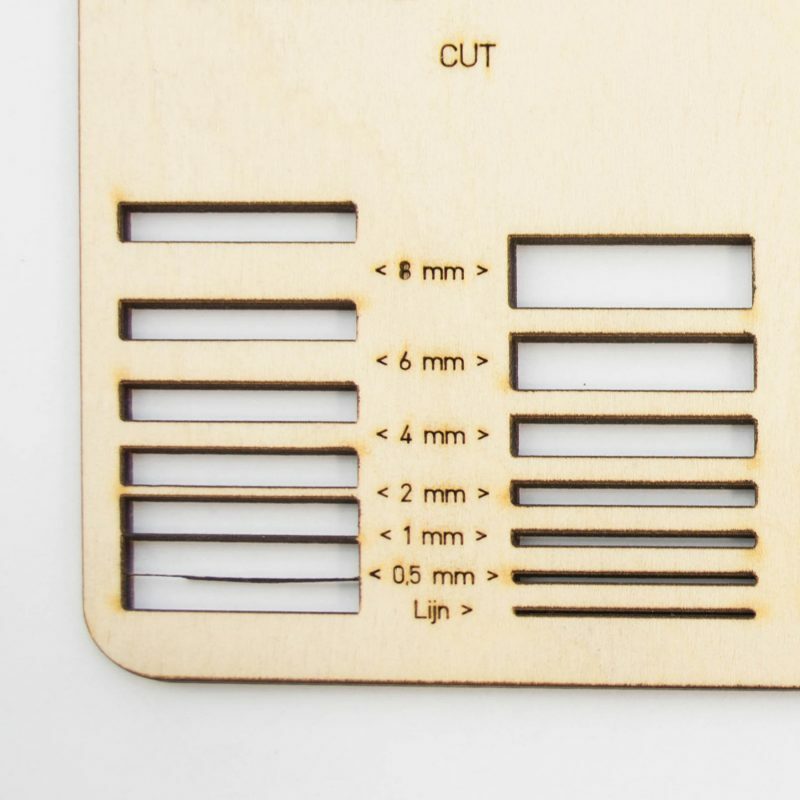

Would you like to have (parts of) your drawing vector engraved? Put the different lines in a separate layer and color the lines according to below overview.

| Layer name | Line colors |

|---|---|

| cut | blue(RGB 0,0,255) |

| line engraving | red(RGB 255,0,0) |

| raster engraving | green(RGB 0,255,0) |

Vector engraving is a method of marking where the laser head engraves by moving from left to right down the material. The distance between the lines is less than a tenth of a millimeter to ensure a high resolution detailing. This method is fairly time-consuming and might lead to a longer production time and higher costs. Our CRE8 craftsmen will always assess the work and make sure that we produce your design in the most efficient way possible. Even though the laser actually removes material from the surface, it’s usually not economical to use raster engraving to create real depth.

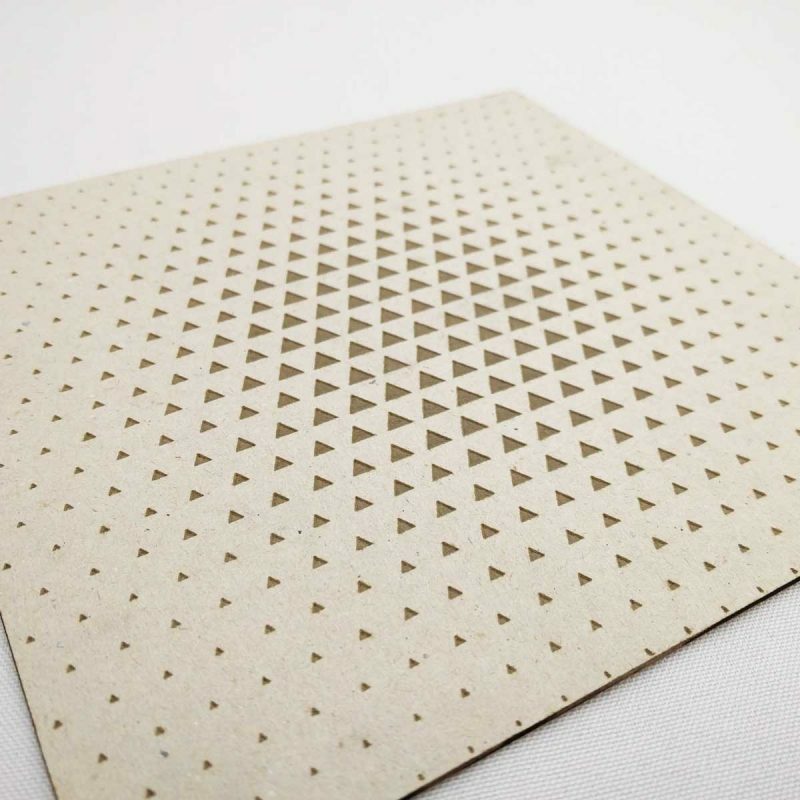

Text and patterns

To engrave a text, the text in the digital drawing needs to be converted to ‘outlines’ (Illustrator: command ‘Create Outlines’, CAD programs: command ‘Explode’). Make the lines around the surfaces in green (check our drawing guidelines below), than it’s clear to us what surfaces need to be engraved.

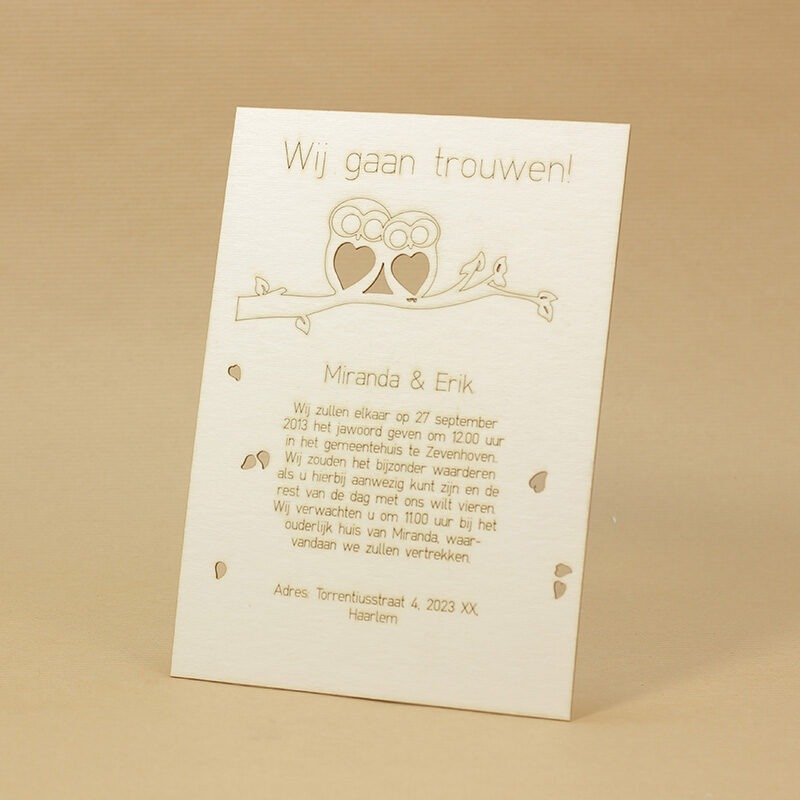

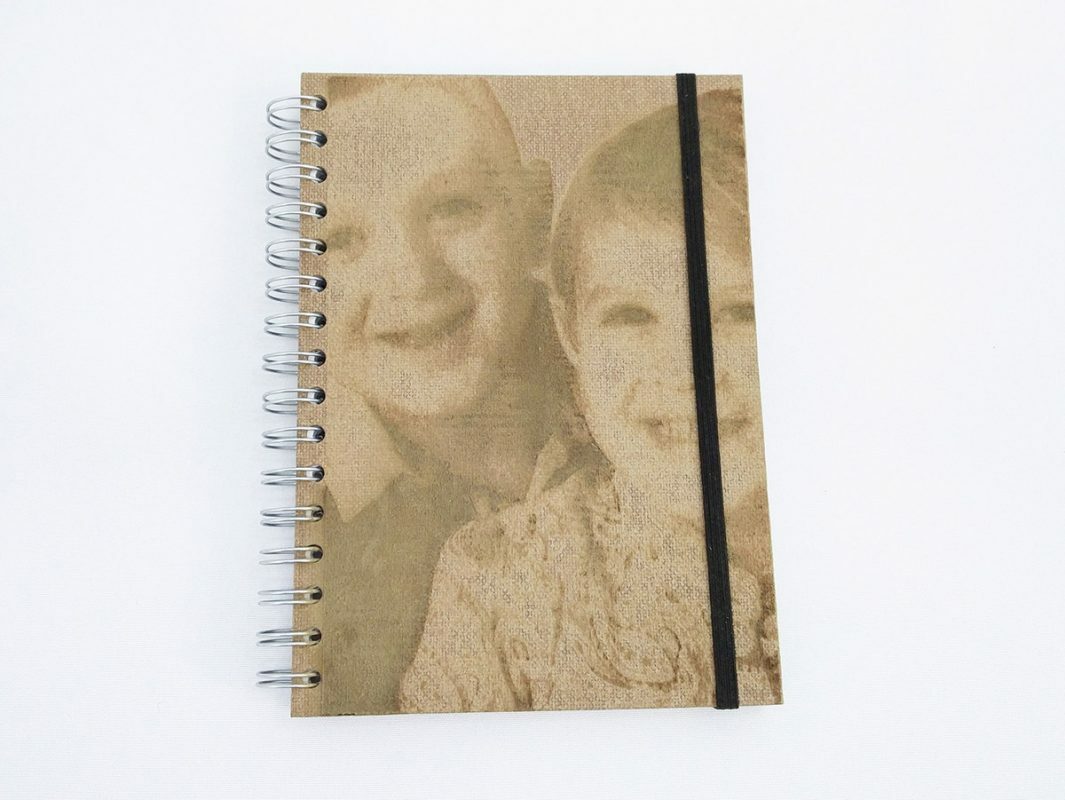

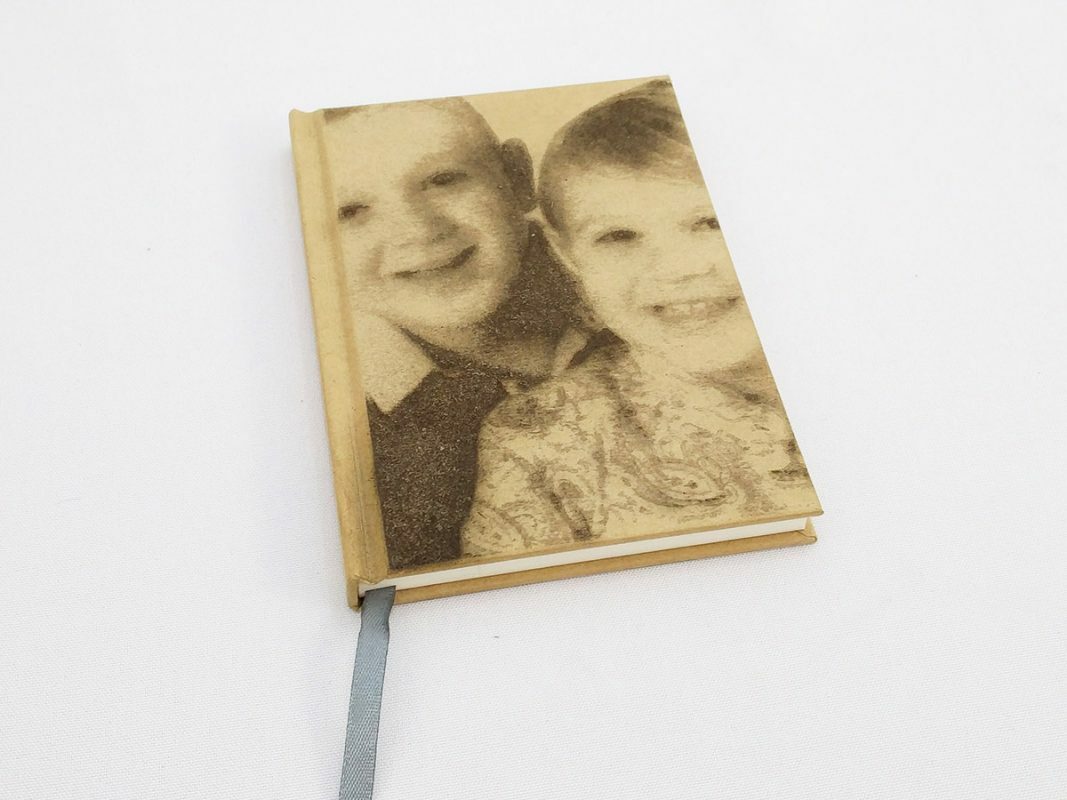

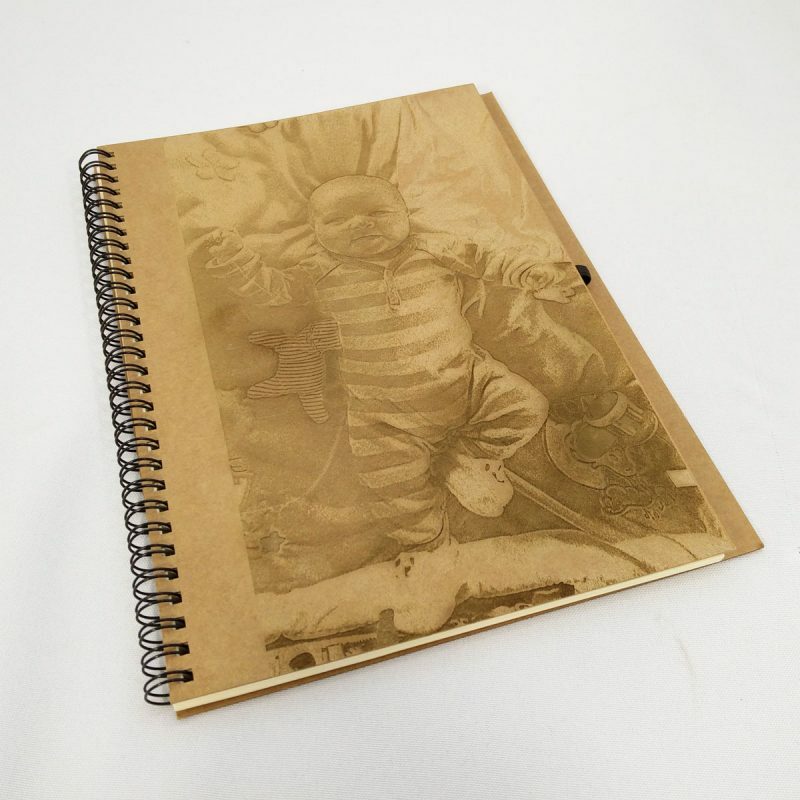

Images

Images (built up from pixels) we can directly engrave on different surfaces, like wood and cardboard. Not only on sheet material, but also on products like notebooks, agendas, wine boxes, cutting boards and small furniture up to 40 cm in height! The image should be converted to a bitmap though. We could do that for you as well.

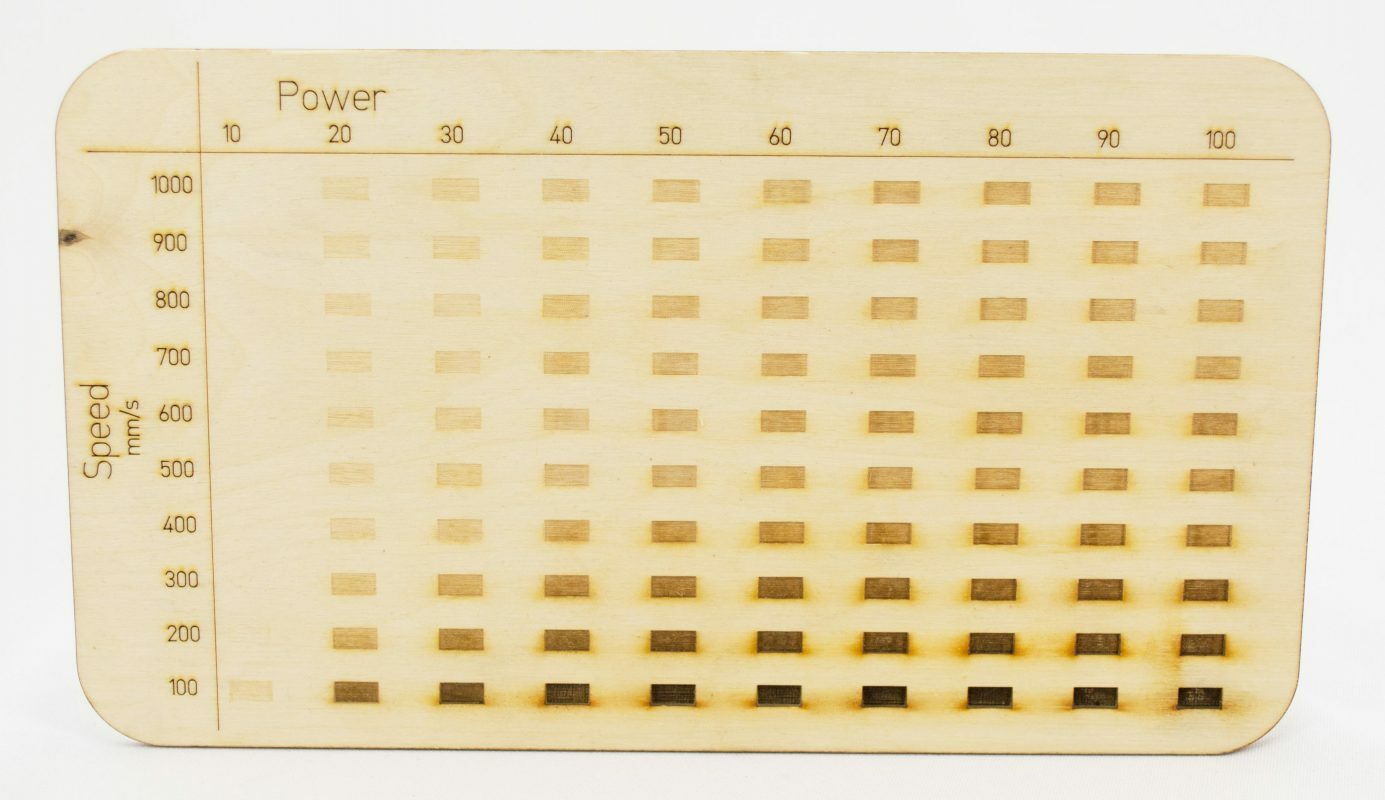

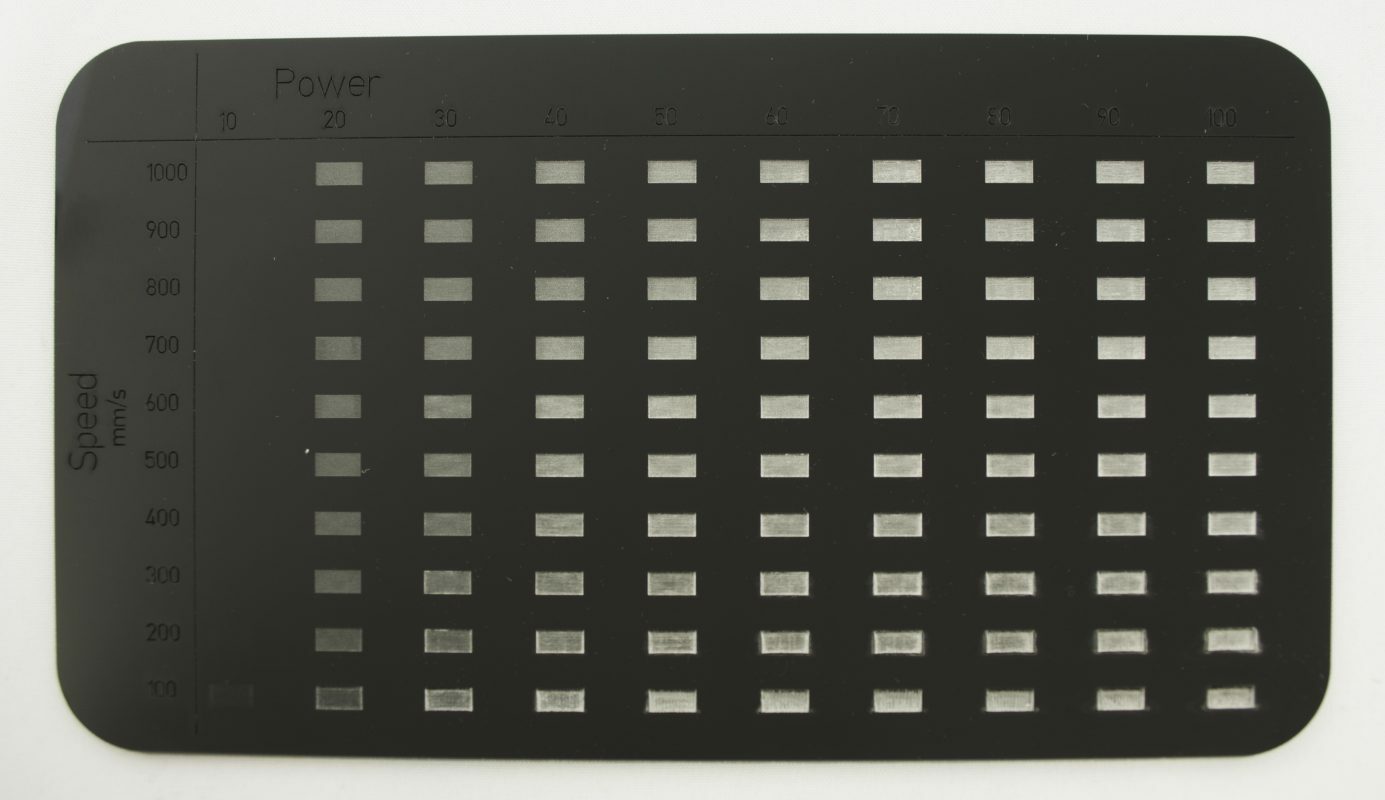

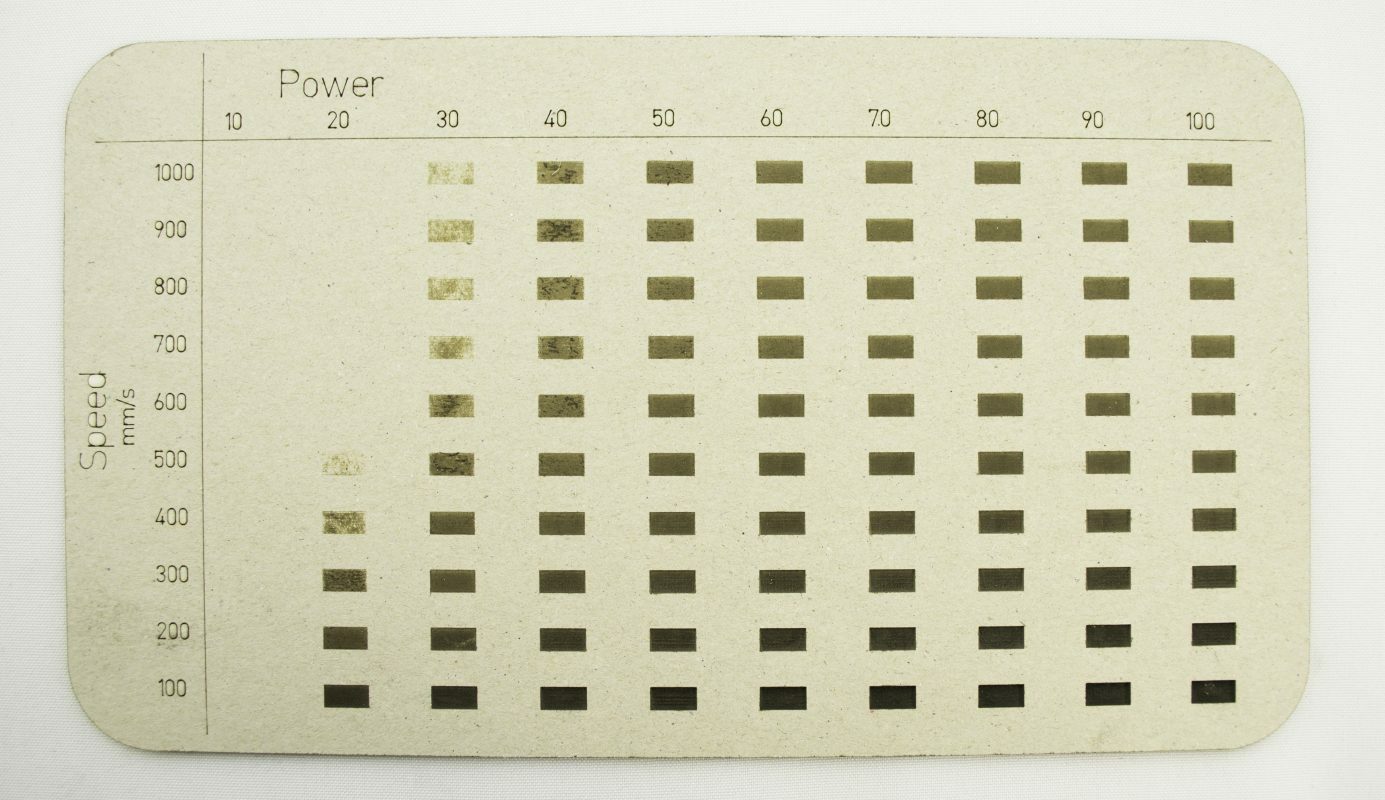

Variants in engraving speed and power

By varying the speed and power of the laser we can create different colors and effects. This offers a palette of graphical expressions with a high precision and full of contrast.

| Wood | Acrylic | Cardboard |

|---|---|---|

| Multiplex discolours in different hues of brown | Acrylic becomes matte white (you can only achieve a good contrast with dark colors) | Cardboard discolours in different hues of brown |

Costs: depends on size, check our overview.

Guidelines laser engraving

Would you like to have (parts of) your drawing raster engraved? Put the different surfaces in a separate layer and color the lines according to below overview.

| Layer name | Line colors |

|---|---|

| cut | blue(RGB 0,0,255) |

| line engraving | red(RGB 255,0,0) |

| raster engraving | green(RGB 0,255,0) |

ENGRAVING WOOD

Engraving on wood can lead to very good results, for texts, patterns and as well as images. Wood can discolour in many different hues resulting in beautiful representations of images, full of contrast.

ENGRAVING PLASTIC

The PP foils are not suited for engraving, the contrast between material and engraving is too little. With acrylate on the other hand good results can be achieved for texts and patterns, and to a lesser extent images (only a few hues of white possible).

ENGRAVING CARDBOARD

Solid cardboard is well suited for engraving, for both texts, patterns and images. For example to create a beautiful engraving on a notebook or dummy. Corrugated cardboard is not suited.

ENGRAVING LEATHER / TEXTILE

We don’t have a lot of experience in this. Of course leather suits very well for engraving and probably other natural materials like cotton and linen would give nice results as well. Probably engravings on synthetic fabrics result in low contrast compared to the rest of the material.

ENGRAVING METALS

In contrast to cutting we are able to engrave on metals. To do so we add a special paste that is burned on the metal. Anodised aluminium can’t be engraved though.

A SELECTION OF OUR CLIENTS: